We achieved very favourable results in 1999 with our small model called Alpha. We therefore decided to build a large prototype in 2000. We were given a grant from The Norwegian Research Council of 1 million NOK.

The Bravo was to be the large-scale model that we wanted to deploy in a real river. We had to seek a suitable site, make the construction and at last build and install it in the river or canal.

WPI was fortunate to draw on the expertise and professional know-how of the following companies:

• Aker Maritime ASA,

They did engineering, calculations and detail design.

• Stork AS delivered step motors and software.

• Goltens Norway AS did construction work.

WPI AS did:

• Overall management

• Site management

• Installation

• Launching

• Built the foils

• Developed the controller system

Evensen and Kaare participated also in every other type of work where an extra hand was needed. We were very proud at the 14th of september when we shipped our BRAVO on a truck to the Skollenborg excite canal.

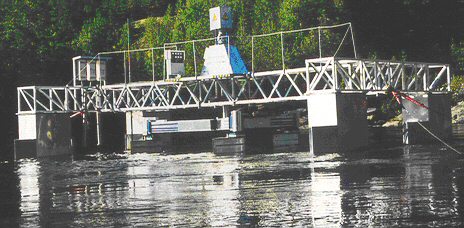

Bravo was launched at Skollenborg power station in august 2000.

Buskerud Kraftproduksjon AS (BKP) was most helpful in finding a site for us and we chose downstream Skollenborg, a Kaplan site, at Kongsberg. We deployed Bravo and started testing. In November a 100 year flood, came, and Bravo capsized. It was salvaged and grounded.

In 2001 WPI found, and again with the assistance of BKP, a new site, Pikerfoss Power Station, 7 km upstream of Kongsberg. This is a Kaplan site. Bravo was deployed at the end of the 2, 5 km discharge tunnel in the spring and we started rebuilding and testing.

Thee years were spent in testing out the different programs for governing the controlling step motors. In addition we tried to find the ultimate combination of motors and controllers. We found that our theses were correct but we needed new controllers and positioning devices.

In 2002 we used a long time to find the right equipment and to do testing before deploying Bravo! We also spent a large amount of cooperative work together with the water department of SINTEF of Trondheim. They did more track calculations and pre-programming together with us. BKP gave us full cooperation in electrical and mechanical work.

We built an indoor test basin in 2003 to be able to perform scientifically professional tests that could be quality controlled.

This picture is taken during the testing period.

NTNU, SINTEF and WPI did testing and scientifically proved that the WPI turbine has a yield of 50 % in a broad range of water speed. The dam factor was tested and found to be calculable and negligent.

The governing data program was tested and honed on the little Alfa 2 model as part of the work. When we were satisfied this program was transferred and downloaded to Bravo at Pikerfoss.

Further testing and work on the BRAVO showed that it worked as intended. Therefore, after long and interesting hours, and days, not to mention months and years we succeeded with the BRAVO prototype. It worked as expected at last and we have a proof that our thesis is correct with the layout, and controlling devices that we have built. We have an Active Pitch Controlled Vertical Axis Water Turbine!

It is called the WPI turbine and is the first in the world!

This picture shows the central part of the turbine with the Vertical Axis that is the connection between the gear and generator and the tree legged star from which the foils are suspended.

The foil can here be clearly seen together with the arm of the “star” and the encapsulated controller and motor.

|